Value gained by Carrot farmer: big difference in quality

- ExploGrow™ (SumaGrow) bio-organic fertiliser out-performed all the 5 Carrot farm lands on quality by +28.71% with a yield increase of +12.8% (on average)

- Carrot quality: on average ExploGrow™ resulted in harvesting +12.88 tons per hectare more Carrots “fit for market”

- Carrot yield: on average ExploGrow™ resulted in yielding +8.02 more tons per hectare

- The market value of the additional ExploGrow™ Carrots “fit for market” added up to +R41,216.00 per hectare

- Return on investment: 1,032%

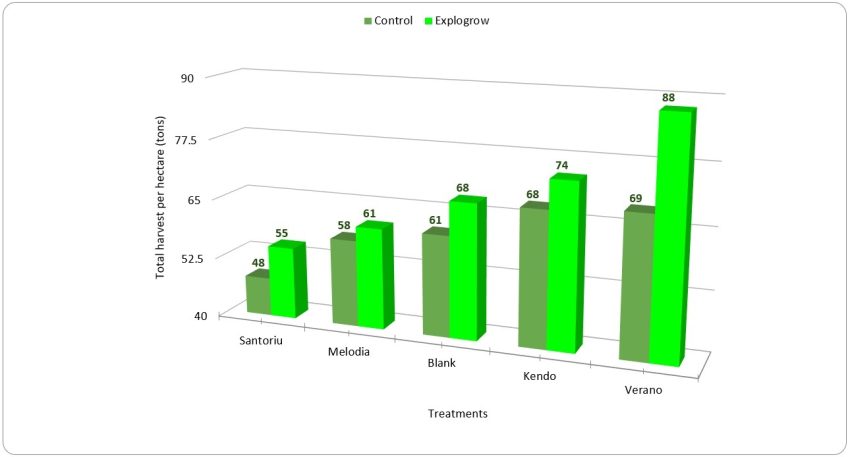

Carrot harvest data in tons per hectare (Increased yield)

Carrot variety: Verano

- Untreated 68.97t/ha

- ExploGrow™ treated 87.98t/ha

Increased yield: 19.01 tons per hectare =

+27.6% more carrots harvested

Carrot variety: Santorin

- Untreated 48.25t/ha

- ExploGrow™ treated 54.78t/ha

Increased yield: 6.56 tons per hectare =

+13.5% more carrots harvested

Carrot variety: Kendo

- Untreated 68.16t/ha

- ExploGrow™ treated 74.17t/ha

Increased yield: 6.01 tons per hectare =

+8.8% more carrots harvested

Carrot variety: Melodia

- Untreated 58.48t/ha

- ExploGrow™ treated 60.66t/ha

Increased yield: 2.18 tons per hectare =

+3.7% more carrots harvested

Carrot variety: Blank

- Untreated 61.12t/ha

- ExploGrow™ treated 67.50t/ha

Increased yield: 6.38 tons per hectare =

+10.4% more carrots harvested

On average ExploGrow™ (SumaGrow) out-performed every untreated Carrot farm land by 12.8% (8.02 tons per hectare), however there was a very big quality difference in terms of marketable Carrot quality.

The improved quality of the ExploGrow™ treated Carrots enabled the farmer to deliver +28.71%more Carrots “fit for market” compared with the untreated Carrots as illustrated below:

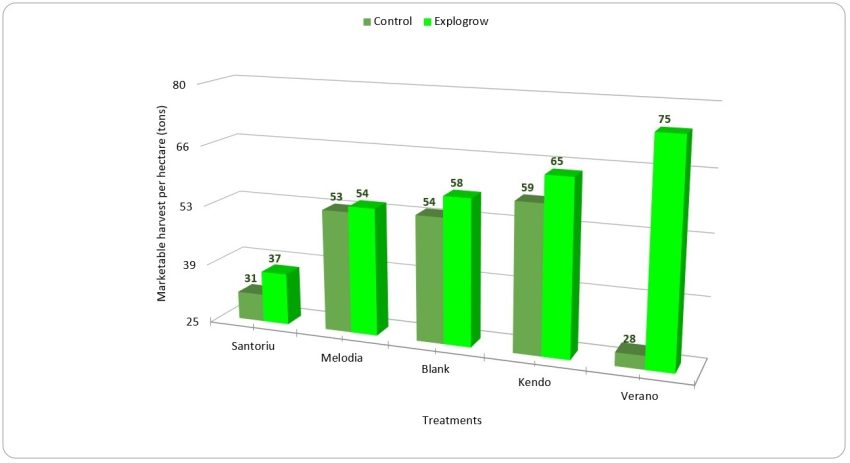

Marketable Carrots (quality fit for market versus crop damage)

The untreated Verano block showed signs of being quite infested with root pathogens. The quality of this block was by far the worst of the tested areas. This was in spite of conventional preventative action. The quality and yield of the carrots in ExploGrow™ treated Verano block is a triumph under these circumstances.

On this particular farm, the soils have high concentrations of crop damaging Root-knot Nematodes.

Carrot variety: Santoriu

- Untreated 31t/ha

- Treated 37t/ha

Carrot variety: Melodia

- Untreated 53t/ha

- Treated 54t/ha

Carrot variety: Blank

- Untreated 54t/ha

- Treated 58t/ha

Carrot variety: Kendo

- Untreated 59t/ha

- Treated 65t/ha

Carrot variety: Verano

- Untreated 28t/ha

- Treated 75t/ha

Differences in marketable crop quality after applying ExploGrow™

- the ExploGrow™ (SumaGrow) treated lands out-performed all untreated Carrots lands

- an additional +12.88 tons per hectare Carrots “fit for market” harvested (+28.71%)

- the market value of the additional ExploGrow™ Carrots harvested equalled +R41,216.00 per hectare

Rain and moisture are captured by the soil instead of remaining

Rain and moisture are captured by the soil instead of remaining