SumaGrow demonstrated an increase in the number of saleable pumpkins produced as compared to the untreated control. The data presented in this study suggests that the larger number of saleable pumpkins from the SumaGrow treatment, as compared to the untreated check, was due more to an improvement in pumpkin quality than an increase in total pumpkins produced.

The quality factors affected were size, disease resistance, and maturity. SumaGrow appeared to specifically influence pumpkin maturity and also had fewer diseased pumpkins than the untreated check. SumaGrow treated plants had larger, darker green leaves than the untreated check.

The plant growth and yield response to the product was significant and should be of economic benefit to a grower.

Plant Growth: The plants in SumaGrow plots were similar in appearance to those of the untreated check until just prior to the start to the start of blossom formation. At that time it was observed that the leaves of the SumaGrow treated plants were becoming larger and darker green than the untreated check plants. By mid-way through fruity set, plants in the SumaGrow plots had larger and darker green leaves than the plants in the untreated check plots. The larger dark green leaves became very noticeable on the SumaGrow plants because they formed a very dense leaf canopy.

Fruit yield, quality, and disease: The saleable yield data indicates that the SumaGrow treatment produced more saleable pumpkins than the untreated check. There was also an effect on pumpkin size. There was an increase in the number of pumpkins in the 10-39 pound range as compared to the untreated check.

The number of green pumpkins is given in Table 2. SumaGrow treated plots produced fewer green pumpkins than the untreated control. The effect was most noticeable on pumpkins in the 10 to 39 pound range.

Table 3 shows the effect of SumaGrow on the disease of the pumpkin fruit. Disease is a significant economic factor. It reduces the number of saleable pumpkins and it affects shipping quality. Many of the pumpkins are shipped great distances. It is not uncommon for pumpkins to appear to be of sound quality upon shipment but arrive at their destination in un-saleable condition due to disease. SumaGrow treated plants had fewer total diseased pumpkins than the untreated control.

Table 4 shows the total number of pumpkins produced by each treatment. The data shows that the total number of pumpkins produced by the untreated control was slightly greater than the total number produced by the SumaGrow treatment. However, the untreated control treatment produced fewer saleable pumpkins. Total number of pumpkins produced is not an accurate measure of saleable pumpkins. In this particular study, the number of saleable pumpkins appears to influenced more by maturity and disease than total pumpkins produced.

The data suggests that the larger number of saleable pumpkins from the SumaGrow treatment was due more to an improvement in pumpkin quality than an increase in pumpkin numbers. The two primary quality factors were disease and immature pumpkins. SumaGrow resulted in fewer immature pumpkins than the untreated check and also exhibited some disease suppression as compared to the untreated check.

The SumaGrow treatment produced significantly more pounds of pumpkins than the untreated check. Table 6 shows the calculated value per acre of the pumpkins produced using the various treatments. At 30 cents per pound, the total SumaGrow value was $13,612, while the untreated crop’s value was $10,127, which is a $3,484 increase for SumaGrow!

“So far I soaked the treated sea water in the organic compost since last Sunday. I am also doing that for the vegan fertilizer. I will begin experiment this Saturday. I also soaked the broccoli and sunflower seeds overnight in the treated sea water and planted them in compost. Right now, those roots look good, but the sprouts are not ready to harvest yet. One question is if it is a success, how much it is for a bottle of treated sea water?

“So far I soaked the treated sea water in the organic compost since last Sunday. I am also doing that for the vegan fertilizer. I will begin experiment this Saturday. I also soaked the broccoli and sunflower seeds overnight in the treated sea water and planted them in compost. Right now, those roots look good, but the sprouts are not ready to harvest yet. One question is if it is a success, how much it is for a bottle of treated sea water?

On Tuesday, November 12th, more than 100 plants were doused with 1% URB Water seawater solutions. The plants (seen to the right) were thoroughly knocked down with the force and amount of seawater (5 gallons per row) that was administered to the plants in less than one minute. The goal of the watering was to see if the plants could survive the 1% URB Water “death bath”.

On Tuesday, November 12th, more than 100 plants were doused with 1% URB Water seawater solutions. The plants (seen to the right) were thoroughly knocked down with the force and amount of seawater (5 gallons per row) that was administered to the plants in less than one minute. The goal of the watering was to see if the plants could survive the 1% URB Water “death bath”. Bok Choy plants were watered with 1% URB Water seawater treatment and lived. The plants were harvested with the remaining untreated crops on December 6th, which are at the top of the picture to the left. Untreated seawater would have killed all the plants within 4 to 6 hours according to every agronomist that was consulted.

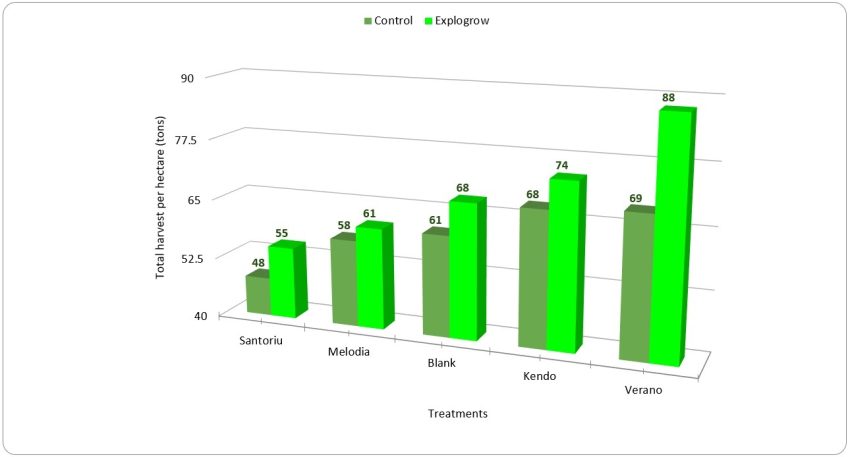

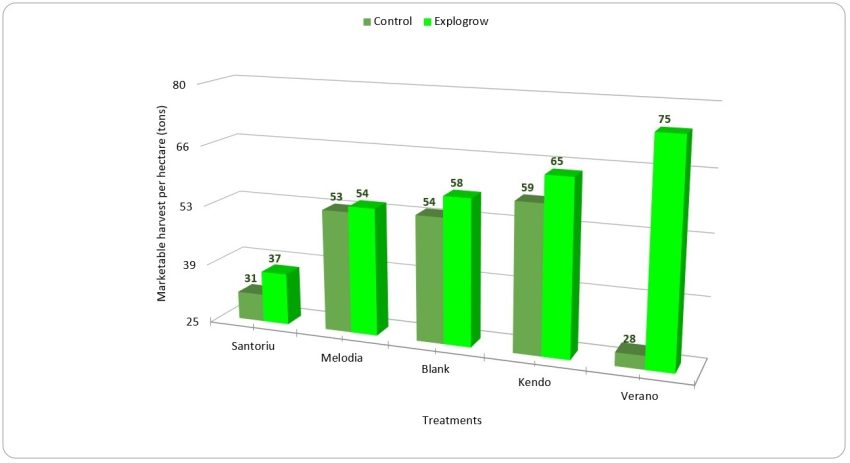

Bok Choy plants were watered with 1% URB Water seawater treatment and lived. The plants were harvested with the remaining untreated crops on December 6th, which are at the top of the picture to the left. Untreated seawater would have killed all the plants within 4 to 6 hours according to every agronomist that was consulted. After seeing the positive effects on other crops, the farmer added SumaGrow (referred to as ExploGrow in report) to his normal fertilizer program, treating all his potatoes. He left no control areas, comparing only year to year results. SumaGrow was applied by pivot irrigation between 8 and 10 liters per hectare. 88 tons per hectare were achieved on one of the 18 potato lands.

After seeing the positive effects on other crops, the farmer added SumaGrow (referred to as ExploGrow in report) to his normal fertilizer program, treating all his potatoes. He left no control areas, comparing only year to year results. SumaGrow was applied by pivot irrigation between 8 and 10 liters per hectare. 88 tons per hectare were achieved on one of the 18 potato lands.

The severe weather created a large bell pepper shortage. Prices greatly increased and Carmelo was able to recoup some of his losses. According to Carmelo “We were the only growers in the area able to bring bell peppers to market.”

The severe weather created a large bell pepper shortage. Prices greatly increased and Carmelo was able to recoup some of his losses. According to Carmelo “We were the only growers in the area able to bring bell peppers to market.”